What Is Dry Dock of Ship and Dry Dock Meaning

1:- Dry Dock Meaning

The maritime industry focuses on long-term performance and keeping things running smoothly. Think of ships like your cars or bikes, just much bigger and more complex. To keep ships running smoothly we require dry docking where ships go for regular maintenance that can’t be done while they’re at sea. Major repairs and tasks that could be risky onboard are handled safely at these special dry dock facilities.

2:- Why Ships Require Dry Docking

As already mentioned, dry docking is an integral part of the ship’s ability to perform in the long run. Dry Docking at regular intervals offers the following benefits, especially to the ship owners:

- Structural Integrity and Longtime Performance:

- Dry-docking allows for a thorough hull inspection, cleaning of marine growth, debris and addressing major corrosion-related issues which are essential for sustained overall performance of the vessel

- Fuel Efficiency and lower operating costs:

- Proper cleaning of the hull surface improves hydrodynamics which in turn increases fuel efficiency. Timely maintenance of the ship’s machinery reduces breakdown maintenance and increases reliability.

3:- SOLAS Dry Docking Requirements:

The SOLAS(Safety of Life at Sea) convention lays down statutory requirements for dry docking. Here are some of the most important requirements:

- Cargo ships have to be dry-docked twice in 5 years.

- The interval between two consecutive dry docks shall not be less than 2 years and more than 3 years.

- Failure to dry dock a ship can result in the ship not receiving a safety construction certificate.

Surveys related to dry docking:

- Intermediate Survey: The First Dry Dock is generally planned with the intermediate survey at an interval of 2.5 years from the anniversary date.

- Renewal Survey: The 2nd Dry Docking is planned during the renewal survey for the certificate of registry.

- Periodic Survey: The periodical survey is planned such that it coincides with the harmonized system of surveys.

4:- Documents Required Dry Docking of Ships

The Dry Docking requirements from the docking facility may involve the ship producing certain essential documents. The following may be required:

- The dry dock plan.

- The general arrangement plan.

- The shell expansion plan.

- The ship’s fire-fighting facility plan.

- The tanking arrangement and distribution of commodities.

- The plug plan. (This may be incorporated into the dry dock plan.)

- The Chief Officer’s repair list.

- The ship’s stability information.

- The ship’s general particulars.

- Gas-free certificate (tanker vessels).

- Cargo plan and manifest if docking with cargo onboard.

- Rigging plan (cargo vessels).

- Capacity plan with DWT and displacement /draft scale. After the ship has docked.

- Relevant certificates, subject to effecting survey work.

- Mid-ship section for structural repairs as ordered.

- Detailed location plans of areas where repairs and renewals are required.

- Assembly drawing of propeller shaft, propeller, and stern tube.

5:- Dry Docking Procedure

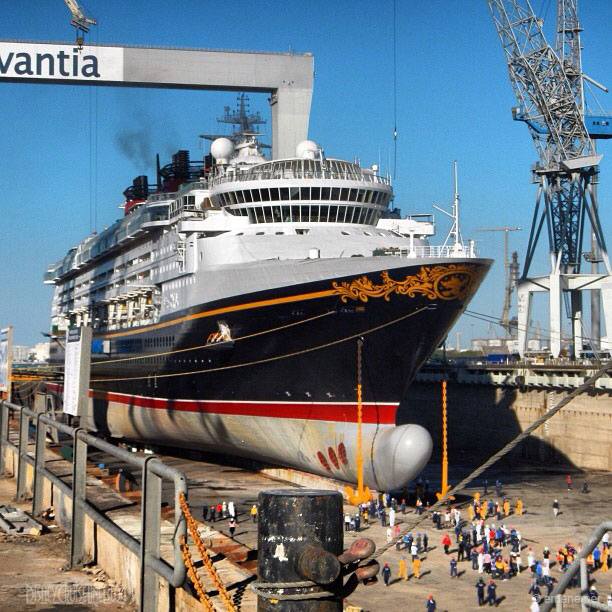

The entire dry-docking procedure is one of the most complex and articulate procedures. Extreme caution is exhibited, both by the ship’s crew and the dry dock facilities as even the slightest of mistakes can cause a major disaster.

The most commonly used type of dry dock is the graving dry dock.

Here is an overview of the dry docking procedure for a graving dry dock:

5.1:- Enter the Dry-Dock Area

- After completing all necessary preparations and port paperwork, the vessel proceeds to the dock, assisted by tugs and shipyard personnel.

- The blocks are arranged according to the shipyard’s Docking plan.

5.2:- Pumping Down the Dock and Vessel “Taking” the Blocks

- The size of the vessel plays a major role here. Water is pumped out of the dock in about 8-10 hours, generally overnight.

- Before the vessel is rested on the block, specialized dive teams ensure the block structures are in the correct location.

- Accurate stability considerations are essential to ensure a safe docking operation

5.3:- Ranging the Cables

- After the dock dries, the cables, also known as anchor chains, are ranged on the bottom.

- After that, the quality and condition of the anchors and cables are assessed by measuring and inspecting them, and any damaged pieces are fixed or replaced as needed.

5.4:- Hull Painting

- One of the main reasons for dry-docking is hull painting, which involves washing, blasting, and painting the ship to guarantee effective vessel operations for the ensuing five years.

5.5:- Opening Sea Chests and Overhaul of Sea Valves

- The sea chest is a hull recess that allows seawater to be incorporated into the engine room’s cooling systems.

- During the dry-docking procedure, this area is opened for cleaning, inspection, and painting.

- All ship-side sea valves undergo the necessary inspections and overhauls simultaneously.

5.6:- Necessary Repairs and Maintenance

- Teams take advantage of this time to repair engines, pumps, tanks, and cargo areas.

- If any flaws are found, the rudder, propeller, or shafting are repaired.

5.7:- Flooding the Dock

- After completion of all work by the dry dock checklist, the dock is flooded and the vessel and the dock are prepared for departure.

5.8:- Departure and Trials

- The vessel is hauled out of the dry dock with tugs and shipyard workers. Sea trails are conducted once the ship enters a secure anchorage area to verify that all of the machinery is operating as intended. After sea testing is finished, the ship is commissioned back into service.

6:- How Ships are Prepared for Dry Docking?

Dry Docking is no doubt a complex procedure. Hence, they are planned months in advance. Careful ship details and dock preparation are rudiments to a safe docking procedure.

The Dock Master is responsible for safe operations from the dry docking facility’s end. Cooperative Liason between the ship’s Master and the dock master is necessary to execute a well-calculated docking plan.

The Dry Dock facility may require the following from the ship’s master:

- A copy of the vessel’s docking plan.

- Arrival stability details

- Pre-docking condition

Let us now find out how to prepare the ship for dry-docking:

- Create a repair and maintenance list and obtain a drydock handbook if required. Assign respective staff to their specific duties on the list.

- Ship’s Staff to be divided into small groups for supervision of the work carried out by the yard guys.

- Every spare part must be checked and repair items should be kept handy – ready for use.

- It is also recommended to study previous dry-docking reports. In addition to that, the previous clearance measures should also be noted.

- Engine room, tank top, and bilges should be thoroughly cleaned.

- Before dry-docking, the bilge lines should be flushed properly.

- The oil-water separator filter element must be renewed and the entire system should be checked for its appropriate functioning.

- For tankers, every cargo tank should be cleaned and gas-freed.

- Before dry dock, all the heavyweights must be secured.

- Cofferdams and tanks should be sounded and recorded.

- Safety measures and firefighting plans should be discussed before drydocking.

- On-board fire equipment should be checked and kept handy.

- Emergency lighting and generator should be checked before entry.

- Clear marking of valves and chests should be done.

- CO2 total flooding systems should be secured and locked before entry.

- The vessel should approach the dock with an even keel.

7:- Precautions to be Taken During Dry Dock:

Extreme caution and precision are essential to a safe dry docking operation.

Before, during and after the dry docking operations, the following precautions should be taken:

7.1:- Before entry in the Dock:

- Ensure the GM(Metacentric height ) requirements are met as planned.

- Required Draft should be attained.

- The vessel should be at an even keel. (No List)

- Prepare mooring lines and unused mooring lines stowed.

- Proper flags should be displayed as required.

- All tanks should be either empty or full. The free surface effect should be kept to a minimum.

- All Machiner Parts and other movable items should be secured.

- Ship power, fire main, fresh water, and telephone connections to be ready.

- Overboard discharges to be shut.

- Gangway accommodation ladders should be stowed properly.

- The ship’s crew should stand by and attend to the moorings as required

7.2:- While Entering the Dock:

Times of the following to be logged down:

- When the vessel enters the dock.

- When the gate closed

- When pumping out commenced.

- When vessel sewed

- When pump out is completed.

7.3:- After Vessel Docked:

- Soundings of Tanks and Bilges throughout the vessel should be taken.

- All necessary records are to be kept onboard and a copy may be required by the Dock Master

- Plugs are to be removed if draining of the tanks is required.

- All removed plugs are to be in the safe custody of C/O.

- Bridge equipment, gyro shut down, heading recorded.

8:- Dry Docking Inspections and Repairs

The Dry Docking Survey Checklist, usually prepared by the dockyard details everything about the procedure including maintenance work to be carried out and repairs to be taking place. A copy of such a checklist is made available to the master of the vessel.

Generally, the following inspections and repairs are carried out in a dry dock:

- Shell Plating: The shell plating is to be examined for excessive corrosion, deterioration due to chafing or contact with the ground, and undue unfairness or buckling.

- Cargo Holds: Tank top plating, close-up surveys, inspection of bilge system systems, and general condition of cargo holds inspected.

- Sea chest: The sea chest is a recess in the hull of the ship that provides an intake of seawater for the cooling systems in the engine room. This area is opened during the dry-docking process for cleaning, inspecting, and painting.

- Overboard valves: All ship-side sea valves are inspected and overhauled as required.

- Sea suction valves: Inspection & overhauling of sea suction valves.

- Echo Sounder: The echo sounders are serviced and the cables are checked for continuity and earth after cleaning the connections in the terminal box. The transducer plates are cleaned and a coat of fish oil is applied to the transducers.

- Doppler fittings: These equipment are to be serviced and calibrated. Before departure from the dock, they are tested for water and air tightness.

- Stern frame: Tested for clearance between the propeller and stern frame because if there is excessive clearance the ship vibrates excessively.

- Rudder: Rudder for damage and leakage, drain plugs to be opened to find evidence of leakage, locate the leak by air/hydro-test, repair, and retest, rudder bearing condition including pintle, lock nut tightness, and pintle clearance and smoothness of rudder movements to ascertain if the rudder is required to be removed for necessary repairs.

- Rudder trunk and stern frame for general condition and possible damages/cracks.

- Propeller: Checked for the condition of propeller blades and polishing.

- Anodes: Replaced in dry dock. ICCP system is inspected, calibrated, and tested by the surveyor.

- Anchors: Lowered in dock and checked for smooth functioning of hinges and no cracks are developed on any parts of the anchors.

- Chain cables: Anchor chains are ranged (laid up on the dock floor) for testing and measurement of links. Any link that is corroded is removed and replaced with a new one. A certificate issued with it.

An actual dry dock checklist may look like this, click here.

9:- Conclusion

Shipowners can ensure smooth fleet management if an appropriate dry-docking facility is selected with due regard for location, capability, cost, and reputation. The safety measures followed at every stage of the process safeguard the vessel as well as the personnel involved, adding to the efficiency and safety of maritime operations.

10:- Dry Dock FAQs

Dry Dock is a dedicated service facility where cargo ships are sent for maintenance and necessary repairs that are too extensive to be carried out onboard.

Dry docking costs can vary widely based on the size of the vessel, the extent of repairs and maintenance needed, and the specific services utilized. On average, dry docking a large cargo ship in Dubai can cost between $500,000 to $1.5 million.

Generally, ships are required to undergo drydocking at least once every five years, although this can vary depending on the type of vessel, regulatory requirements, and operational conditions.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.