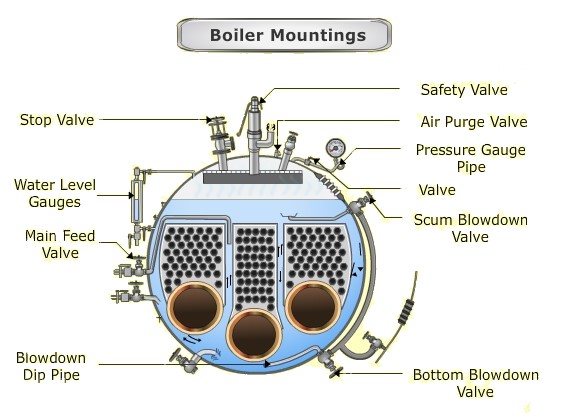

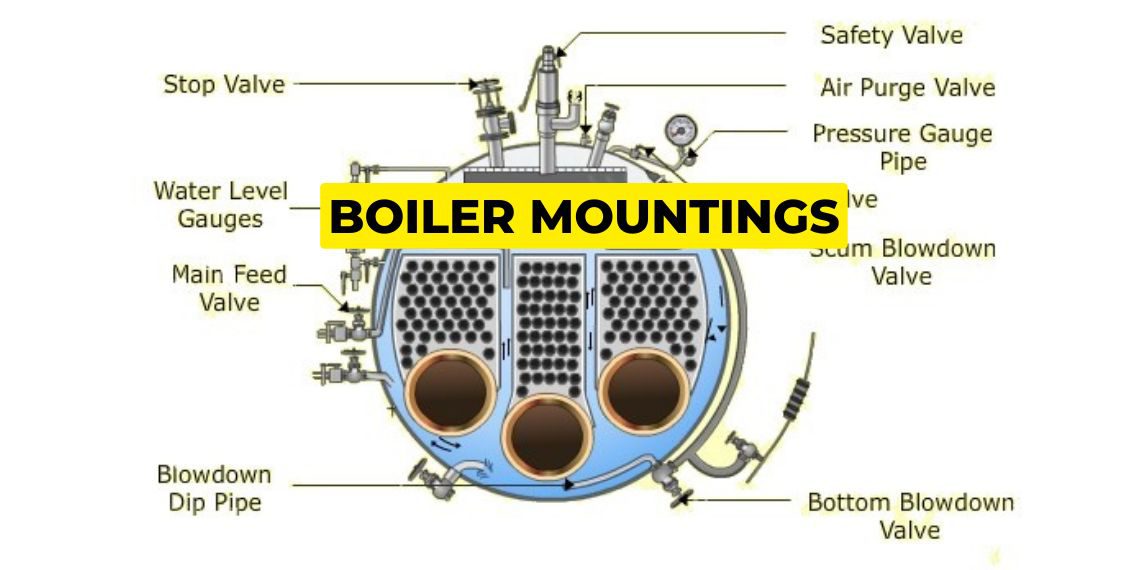

Boiler mounting on ship | Safety Valve | Feed Check valve | Scum blow down valve| Blow down valve | Air vent |

Various valves and fittings are required for the safe and proper working of a boiler. Those parts attached directly to the boiler and without which the boiler can’t work safely are referred to as the boiler mounting.

These are some mountings mounted on boilers on board a ship:

Safety valve (boiler mounting):

A safety valve is a boiler mounting used to protect the boiler from over pressurization for the safe working operation of the device. There have been instances where boilers have exploded because of over pressurization as the safety valve did not lift.

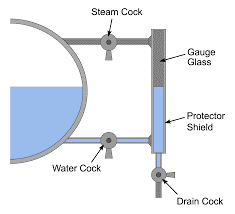

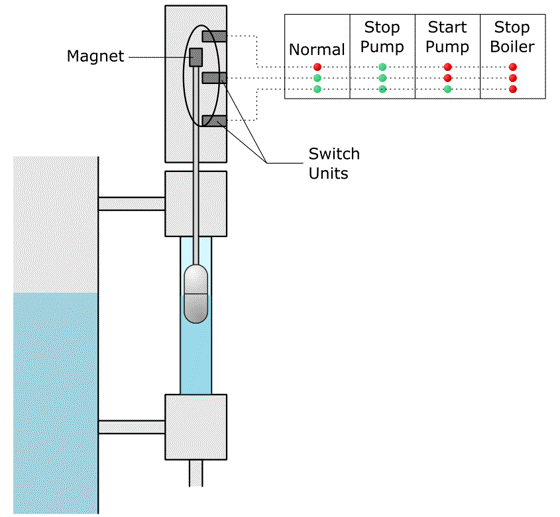

Gauge glass (boiler mounting):

A gauge glass is a boiler mounting which is a water v/s steam measuring device which visualizes the level of water and steam which is very important for safe working of the boiler. Ship owners have lost millions of dollars because the boiler got completely damaged as the boiler kept firing with very less water inside the water tubes.

Feed check valve (boiler mounting):

A feed check valve is a boiler mounting which is a combination of Non return valve and screw down valve used to feed the boiler and to control the supply of water as needed in the boiler.

Steam pressure gauge (boiler mounting):

A pressure measuring device is fitted on the boiler steam drum to read the pressure inside the boiler. This pressure gauge is a specially certified pressure gauge.

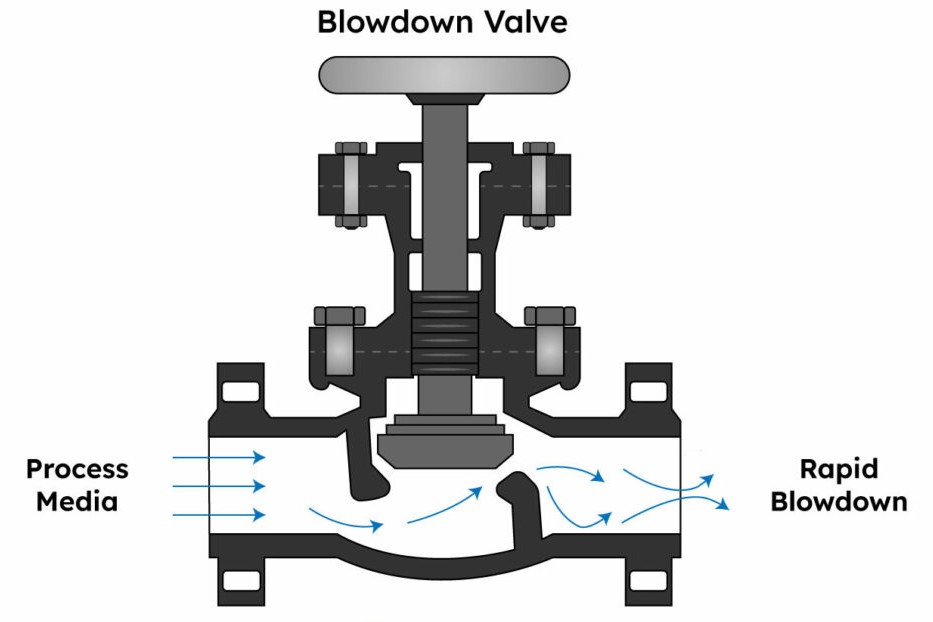

Boiler blow down valve (boiler mounting):

A valve is fitted at the bottom of the boiler which is used to empty the boiler or used to remove the impurities from the boiler like mud, sand, and other sediments to avoid different types of corrosion.

The water which is circulated inside the boiler tubes and drum may contain dissolved and undissolved solids. During the steam-making process, i.e. when the boiler is in operation, the water is heated and converted into steam. However, these dissolved solids do not evaporate and get separated from water or steam, and they tend to settle at the bottom of the boiler shell due to their high density. Dissolved and undissolved solids lead to scaling, corrosion, erosion etc.

To prevent these problems boiler blowdown is done through the blowdown valve. The boiler blow-down valve is fitted on the drain line of the boiler.

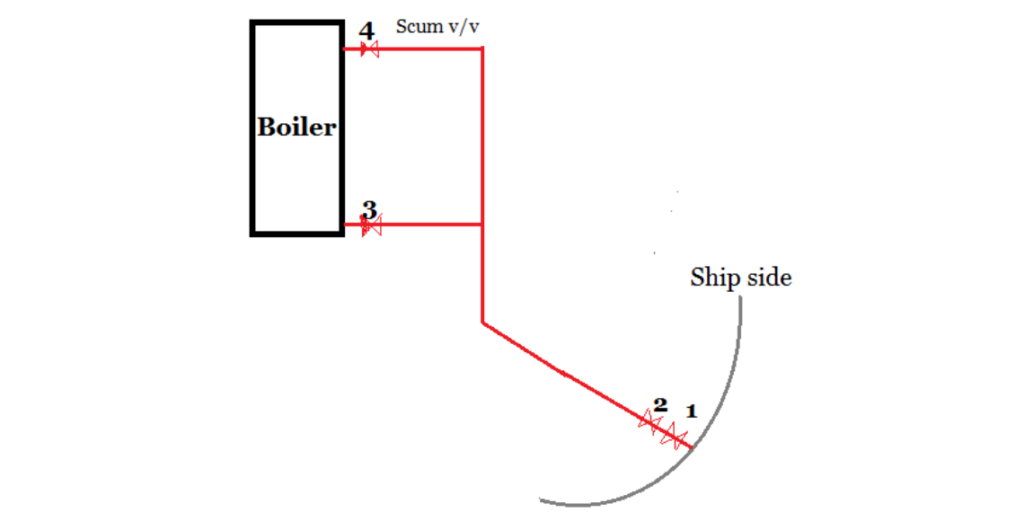

Scum blow down valve (boiler mounting):

Scum is also known as floating debris, Scum blow down valve is a boiler mounting fitted at the boiler drum. This mounting is used to remove the floating debris or impurities floating on the water inside the boiler. By removing the scum, we are reducing the conductivity of boiler water which helps in reducing the corrosion of the boiler for better performance.

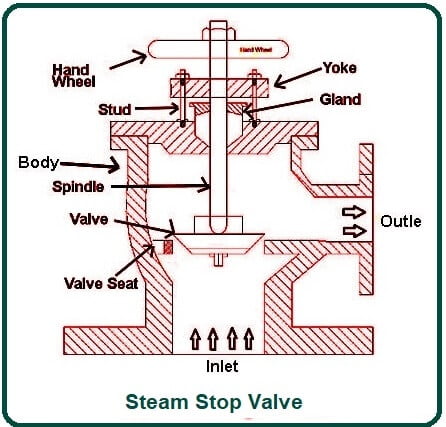

Steam stop valve:

A type of non-return valve is fitted at the top of the boiler steam drum which is used to regulate the flow of the steam. Generally, we keep this valve either in full open condition or in full closed condition. Steam stop valve is a type of screw down valve i.e; it is manually operated valve.

When the boiler pressure achieves 5-6 bar then slowly open the steam stop valve to prevent the water hammering or to warm the steam pipeline. After every 2.5 years and on every dry dock of working steam stop valve should be inspected properly or overhauled then set back to its original position.

Low water level shut down:

To avoid a boiler explosion or damage from the low level of water inside the steam drum, so here we have a Low water level shutdown. It is a type of trip that is mounted with boiler gauge glass. According to the gauge glass reading whenever the water level reaches a low level then the fuel supply automatically cuts from the burner and the alarm will raise.

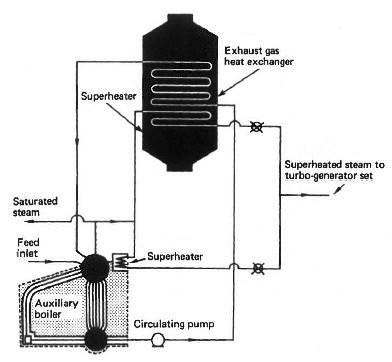

Exhaust Gas Economiser:

A boiler utilizes the exhaust gas temperature to convert water into steam. Here exhaust gas coming from the main engine has 250-300 degree centigrade which hits the turbine part of the turbocharger. Then the exhaust gas moves to the Exhaust Gas Economizer where water circulation takes place inside the tube from the water drum to the steam drum with help of circulating pumps.

When exhaust gasses pass through the exhaust gas economizer the heat exchange takes place between the tube and its surrounding. As the temperature is too high the water will get converted into steam. After heat exchange takes place the exhaust gas goes into the atmosphere.

Air vent cock (boiler mounting):

An air vent cock is fitted in the head of the boiler steam drum to avoid imploding of the boiler when it is depressurized because of vacuum formation inside the boiler. Or when initially raising the steam pressure, to vent out the air such that corrosion doesn’t take place.

The air vent is a valve fitted at the top of the steam drum to avoid the two factors from the boiler which are the following:-

1. In the closed compartment of the boiler air is already present inside the boiler while feeding the water. With the help of a feed check valve we feed water to the drum. When the water will get filled to the maximum level that moment air gets displaced from the water drum. It get settled in the steam drum as air contains oxygen which causes pitting corrosion. Along with Carbon Dioxide it will form carbonic acid (H2CO3) when reacting with water which will damage the boiler tube and boiler internals. So we need to remove the air from the boiler.

2) While blowing down the process of the boiler is happening or while removing the water from the boiler so the steam is going on. The produced steam in the steam drum will come down because of gravity. After 5-6 hours boiler will get cool down and the steam gets condensed (remember 1 liter of water producing 1760 liters of steam). Due to which vacuum takes place inside the boiler and boiler might implode. To avoid the vacuum we need to fill the air inside the boiler.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.

Useful article, thank you. Top article, very helpful.

Thank you Yorum,

I hope you liked the blog, there are more blogs like this already uploaded and more blogs are going to be uploaded in this website.

Please check those too.

Team Merchant Navy Decoded