Cooling Water System of the Marine Engine | Why do we need a water cooling system for the marine engine?

Why is it necessary to have water cooling in marine engines?

When combustion takes place inside an engine there are mainly three byproducts:

- Exhaust Gases(30%)

- Work Done(40%)

- Heat(30%)

We must control the amount of heat generated from the engine so that the temperature of the engine does not get too high and cause thermal stress to arise in each component.

The main components which are subjected to high heat during combustion are:

- Piston

- Liner

- Cylinder Head

- Exhaust Valve

The lube oil travels inside through the piston and helps in maintaining its temperature.

A water jacket covers the cylinder liner,head and exhaust valve to maintain the temperature at an appropriate value.

The fresh water is circulated constantly and the flowing water takes away the excess heat from these parts. The temperature of the water must not be very low compared to the engine temperature since the sudden change in temperature can cause thermal stresses to occur.

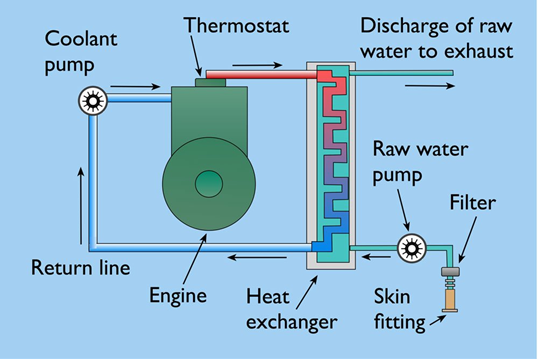

Why is freshwater used instead of seawater for cooling the engine?

Seawater cannot be used for cooling the engine because it is highly corrosive and the replacement of these parts can be very costly.

Therefore fresh water is stored in a tank and circulated to these parts and after the water absorbs all the excess heat it is passed through a plate type heat exchanger, which helps to remove the excess heat from the water with the help of seawater before returning to the tank.

Some of the heated water from the water jacket is also sent to the freshwater generator so that the heat inside it can be utilised to make fresh water more efficient.

Chemicals are periodically added into the freshwater tank in the cooling system so that the quality of the water is maintained and it does not turn corrosive.

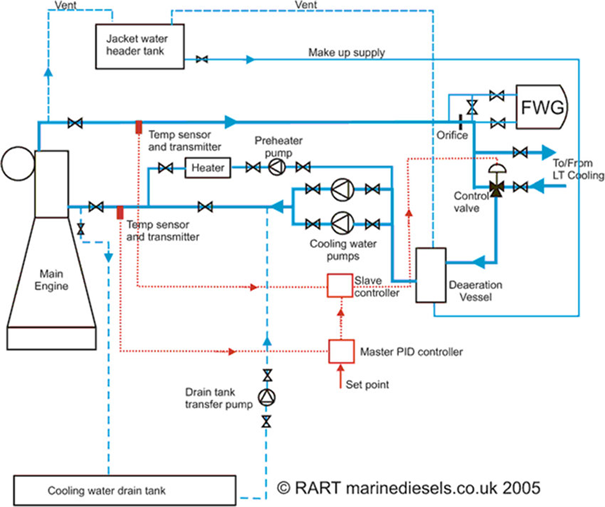

Cooling water system onboard ship

Below is the image of the cooling water system fitted on the ship

The preheater pump is fitted in the system along with a heater such that when the main engine is not running, the preheater pump supplies heated water using the heater in order to maintain jacket water temperature not less than 80-85℃. The simple reason to maintain such a high temperature while the main engine is not running is to avoid cold corrosion and thermal shocks when the main engine is started.

A PID controller is fitted in this system so that the main engine jacket water outlet temperature is always maintained around 88-90℃.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.