Crude Oil Washing

1:- Understanding Crude Oil Washing Onboard

Crude oil washing (COW) is a compulsory task that the masters and officers of the ship handle during voyages that mainly concern the shipment of crude oil. In this way, the transport tanks are cleaned after the completion of the loading process to improve the safety, efficiency, and protection of the environment. It is important to learn about Crude Oil Washing if you are going to go on an Oil Carrier.

2:- What is Crude Oil Washing?

- Crude Oil washing is a process of washing the cargo tanks after the discharge of cargo from the tank to clean the tanks and avoid contamination and mixing of cargo with the next one.

- An important objective is to thoroughly clean tanks to pump float-free oils away for proper treatment which must be done before loading the next cargo.

- This process further ensures the maintenance of environmental safety regulations and the reduction of oil discharge risks.

- It also boosts safety through the limitation of oil spills which may be triggered by misuse of leftover oils.

- First, you start by cleaning the tank. Then, you wash it and rinse it thoroughly. Finally, you make sure to remove any oil properly.

- After cleaning the cargo oil tank, the process is being employed to ensure the tank’s cleanliness and safety standards on board the ships.

3:- Why is Crude Oil Washing Important?

- Prevents Contamination: Oil washing with crude oil rinses the left oil from the cargo tanks, Which reduces the chances of contamination of the next cargo.

- Ensures Compliance: It is used by ships to avoid polluting by applying standards, and consequently, the ship’s activity is favorable to the marine ecosystem.

- Enhances Safety: This residual oil removal method, crude oil washing, is known to significantly lower the risk of fires and explosions associated with ships carrying oil.

- Protects Ecosystems: By reducing the amount of oil residue in the tanks, COW minimizes the risk of pollution. It decreases the volume of oily sludge that needs to be disposed of, which helps adhere to international environmental regulations.

4:- How is Crude Oil Washing Done?

- Preparation: As a security measure, the crew loads the COW system before the actual offloading of the crude oil cargo. This includes ensuring that all pumping equipment including pumps and pipelines are in good condition and properly arranged for use.

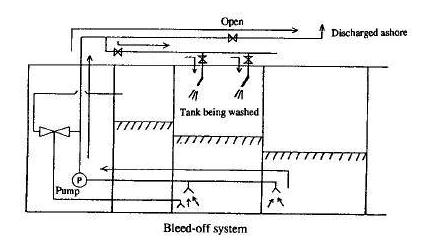

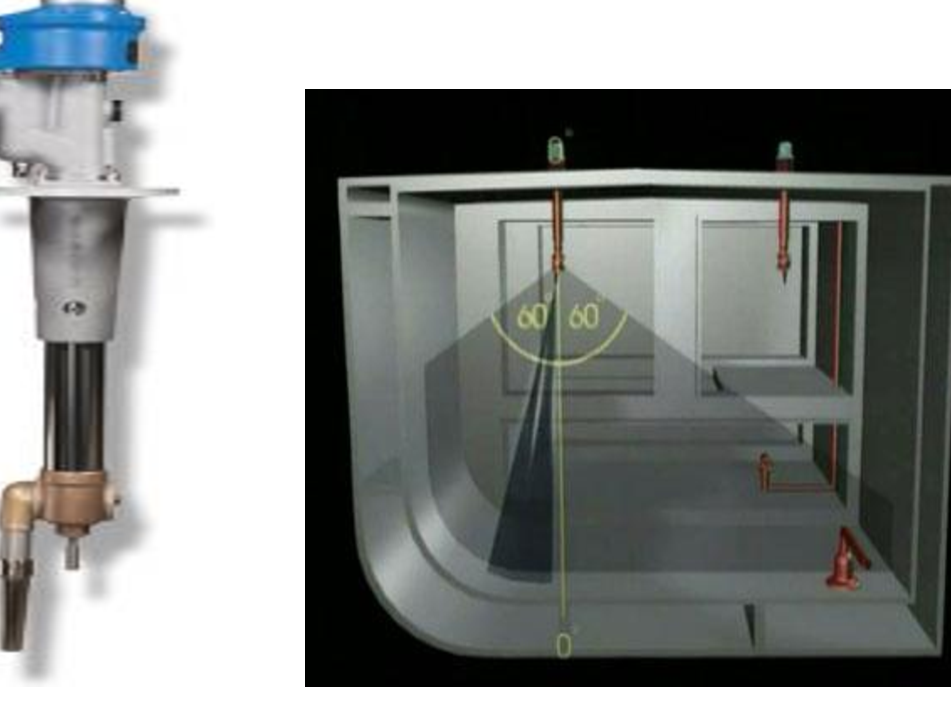

- Spraying Crude Oil: Some of the crude oil is fed through specially designed nozzles on the tank during offloading is another procedure. These nozzles pump the oil at high pressure onto this part of the tank, namely the walls and the bottom.

- Loosening Residue: The high-pressure crude oil spray assists in removing any additional oil deposits and sludge that would still be clinging to the tank walls.

- Collecting Washed Oil: The newly washed-off oil often integrates with the major cargo content and is then pumped out of the particular tank like the rest of the oil. This way, the tanks are cleaned, and more of the cargo is recovered. In this manner, cleaning of the tanks is done, and more of the cargo is gained.

- Final Checks: Also, after the COW process, the tanks’ conditions are inspected to verify they do not contain noteworthy levels of oil. This makes the tanks available for the next load or for any upcoming repair or maintenance if required.

- Learn complete information about Crude Oil Washing and its procedure with our MEO Class 4 Excellence Package which will help you to clear MEO Class 4 and keep you ahead of others.

5:- Benefits of Crude Oil Washing

- Efficiency: The effective process of crude oil washing enables clean and fast tank cleaning which in turn enhances rapid navigation between journeys.

- Cost-Effectiveness: Reusing crude oil for cleaning decreases chemical cleaning agents’ use, which not only makes companies’ backside but also saves money in the long run.

- Safety: Maintaining an adequately low amount of oil on board minimizes the chance of fire/explosions, guaranteeing the ship’s and the crew’s safety.

6:- Challenges Faced in Crude Oil Washing

6.1:- Tank Preparation for Crude Oil Washing

Way before directing crude oil washing, the cargo tanks are cleaned up. This consists of inspecting all the cargo residues, once again, and providing habitable air conditioning by controlling the exhaustion of hazardous fumes.

6.2:- Safety Measures for Crude Oil Washing

None of the operations can be conducted without safety personnel and safe equipment. The crew members should be obsessed with acquiring skills that enable them to follow the regulations about the proper PPE and the relevant oil handling-related procedures.

6.3:- Environmental Regulations

– The procedure of crude oil washing with the aid of environmental protection laws is mandatory. The vessels have to compulsorily stick to the rules and norms of discharging oily waste and other by-products into the sea

6.4:- Monitoring and Control

To ensure crude oil washing projects run efficiently, it’s important to have ongoing monitoring and control. Onboard devices for monitoring and alarms help detect any issues and allow for quick corrective actions.

6.5:- Training and Certification

Proper training, as well as their certification as a crew member in regards to crude oil washing, are of the essence to ensure the competence and proficiency of crew members in the process

7:- Precautions to be Taken While Crude Oil Washing

- Ventilation and Gas Detection: Make sure there is sufficient fresh air in the tank so that there is no accumulation of poisonous gases. To help ensure appropriate measures are in place to monitor and maintain safety within the tank, use gas detectors to track the conditions within the tank at all times.

- Inert Gas System: Make sure to use an inert gas system to cut off the supply of oxygen available in the tank by replacing it with an oxygen-free gas, often nitrogen, to minimize a possible fire outbreak.

- Equipment Inspection: It is required to examine all the assets of COW, pumps, nozzles, and pipelines at a frequent interval and fix them properly to check for leaks or any other problems.

- Temperature Control: Control the temperature of the crude oil used for washing, which, if left to increase excessively, may cause severe operation risks.

- Pressure Monitoring: Another thing is that the pressure concentrations in the system should be monitored to not reach dangerous levels of pressure, as the increase may cause the tank or equipment to break.

- Static Electricity: Measures against static electricity buildup are to be taken to avoid any occurrence of flammable vapors. This includes such aspects as proper earthing and ranging of installations.

- Regulatory Compliance: Comply with all specifications of laws, rules, and regulations governing the operations of maritime organizations and entities locally and internationally.

- Communication: Ensure that members of the crew are communicating with each other during the COW process in order to alter activity or immediately solve problems.

8:- Conclusion

Crude oil washing is crucial for safe, efficient, and environmentally sustainable sea transport. By following advanced procedures and embracing sustainability, the maritime industry can improve its practices and protect marine ecosystems for the future.

9:- Frequently Asked Questions:

Oil washing (the process of washing) is one of the most successful methods that tankers use for this purpose. There are primarily two types of crude oil washing: Manual Crude Oil Washing and automated Crude Oil Washing.

Preventing Contamination, Maximizing Cargo Quality, and enhancing safety, are the main purposes of crude oil washing.

In a general case, every washing of the tank is supposed to be performed at a full level to avoid any remains of oil before the change of oil or before the vessel is laid up.

Crude Oil washing is a process of cleaning the cargo residue from the cargo tanks after the discharging of cargo. It is done to ensure that the next cargo remains free from any kind of contamination.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.