Free Surface Effect in Ship

Table of contents

Introduction

The free surface effect, also known as the free surface phenomenon, refers to the tendency of liquids to move in response to changes in the altitude of the ship, rolling, pitching, etc other movement of the vessel at sea. When considering the free surface effect, we need to take into account the condition of the tank.

1. Free Surface Effect

When a vessel with a slack ( partly full) tank rolls at the sea, the liquid in the slack tank moves towards the lower side during each roll, thereby causing the angle of roll and the period of the roll to increase. Because the vessel behaves as if her GM has been reduced, we say that a slack tank causes a virtual ( imaginary) loss of GM. This is called the free surface effect (FSE)

The virtual loss of GM can be calculated quite easily and is called free surface correction (FSC). To indicate whether the free surface effect has been applied or not, the GM before subtracting the free surface effect is called ‘solid GM’, and after subtracting the free surface effect is called ‘ fluid GM’. In all stability calculations involving GM, it is fluid GM that is to be used.

The free surface effect depends on the length and breadth (mainly breadth) of the slack tank. The volume of liquid in the slack tank has minimal impact.

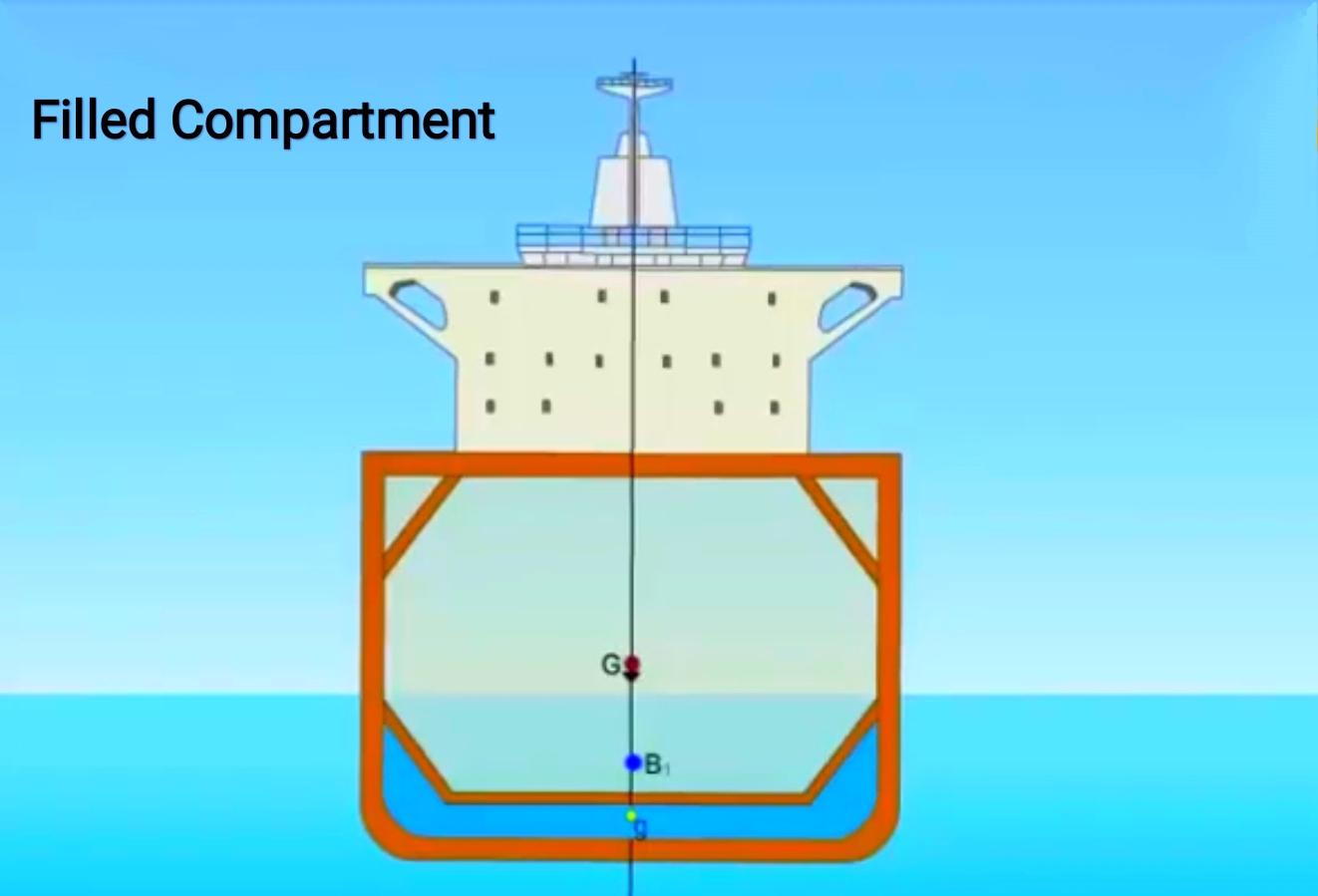

1.1:- Free Surface Effect of Completely Filled Tank

When a fluid such as oil, water, etc., fills the tank, it remains stationary inside the tank and behaves like a static weight or solid weight. It has no adverse effect on the stability of the vessel as there is no change in the center of gravity of the ship as well as the center of gravity of liquid inside the tank does not change.

It has no adverse effect on the stability of the vessel as there is no change in the center of gravity of the ship as well as the center of gravity of liquid inside the tank does not change.

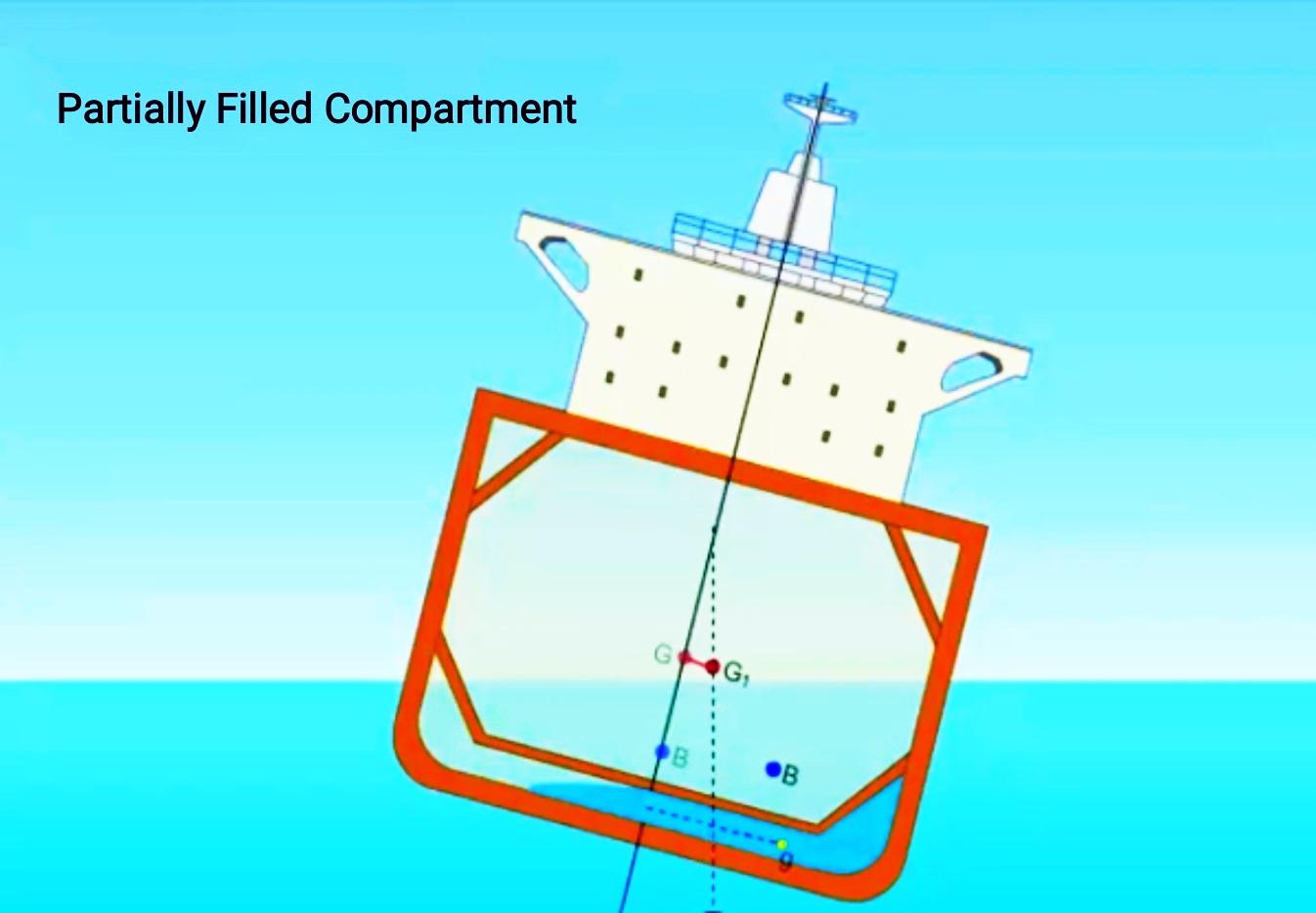

1.2:- Free Surface Effect of Partially Filled Tank

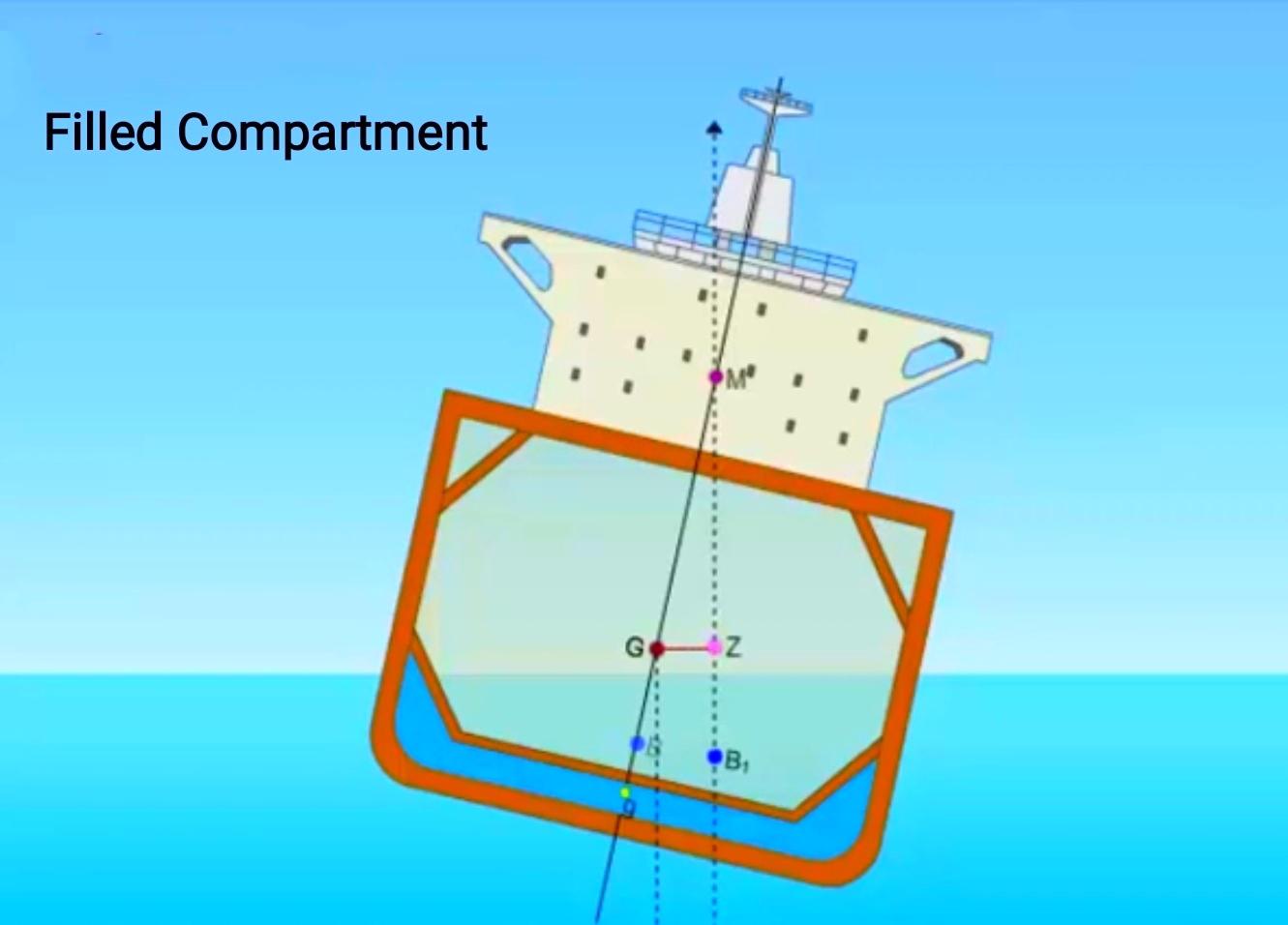

A partially filled tank, also known as a slack tank, indicates that cargo or water partially fills the tank, allowing it to move freely inside. As the ship heels, the liquid moves toward the lower side of the tank, resulting in a free surface effect.

Free surface effect changes the center of gravity of the vessel from G to G1

2:- Free Surface Effect Formula

The Free Surface Correction (FSC) quantifies the vertical shift caused by the movement of liquid within slack tanks on a vessel’s stability. It is calculated using the formula:

FSC = (i * di) / (V * do)

Where:

- FSC represents the Free Surface Correction in meters.

- i stands for the moment of inertia of the slack tank surface about its centerline, measured in cubic meters to the power of 4 (m^4).

- di represents the density of the liquid in the slack tank, measured in metric tonnes per cubic centimetre (t/cm^3).

- V denotes the volume of displacement of the ship in cubic meters (m^3).

- do represents the density of water outside the ship, in which the ship is floating, measured in metric tonnes per cubic centimeter (t/cm^3).

This calculation provides an important insight into the stability of a ship, considering the impact of liquid movement within slack tanks. Additionally, we define the Free Surface Moment (FSM) as the product of the moment of inertia (i) and the density of the liquid (di), representing the tendency of the liquid to affect stability. Simplifying the formula in terms of displacement (W), we can express the FSC as FSM divided by the displacement of the ship (W) in metric tonnes (t).

2.1:- Free Surface Effect Formula in Terms of Ship Displacement

Given that displacement is equal to the product of the volume of displacement and the density of water outside the object, we can substitute the denominator in the foregoing formula with the displacement of the ship in tonnes. Thus, the formula simplifies to:

FSC = (i * di) / W

Where:

- FSC represents the Free Surface Correction.

- i is the moment of inertia of the slack tank surface about its centerline.

- di is the density of the liquid in the slack tank.

- W denotes the displacement of the ship in tonnes.

This simplification leads to the expression: i * di = FSM. Consequently, the formula further simplifies to:

FSC = FSM / W

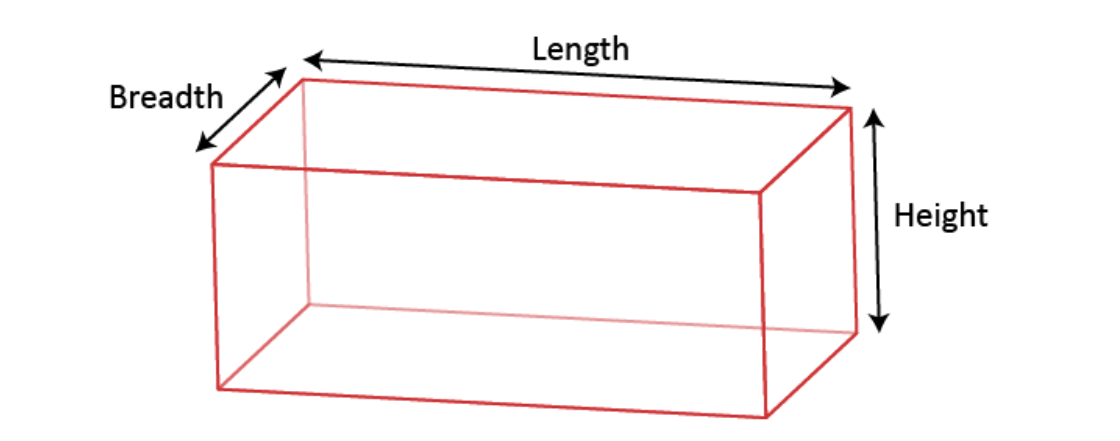

2.2:- Free Surface Effect Formula for Shaped Tank

i = ((L * B^3)/12

FSC = (L * B^3 * di)/12 * W

For box-shaped vessels ‘i’ does not depend upon the depth of the tank and is independent of the liquid inside the tank.

The free surface effect remains constant between 5% to 95% filled level of the tank.

When multiple tanks are slack on a ship, we calculate the Free Surface Moments (FSM) of each tank individually and then sum them to determine the overall FSM. This total FSM divided by the final W of the ship would give the total free surface effect of all the slack tanks.

The stability particulars supplied by the shipyard readily provide the ‘i’ of each tank about the tank’s center line on a ship.

3:- How to Reduce Free Surface Effect

- Pocketing Strategy

Utilizing a method known as pocketing actively mitigates the free surface effect. This technique involves allowing the liquid within a tank to come into contact with the tank’s upper or lower boundaries. This action effectively reduces the width of the liquid’s free surface area, thus minimizing the impact of the free surface effect. - Installation of Swash Bulkheads

Swash bulkheads, or baffle plates, actively restrict the flow of liquids like oil or water during the rolling or pitching motions of a vessel. Positioned in areas such as voids, double bottoms, and tank bilges, these bulkheads play a crucial role in reducing the free surface effect and enhancing vessel stability. - Use of Sluice Valves

The application of free flow (sluice) valves in tanker operations allows for the cross-connection of opposite tanks. While this can increase the free surface effect when connecting large, partially filled tanks, it is essential for managing liquid distribution and stability under certain conditions.

4:- Points to remember about Free Surface Effect

- If the area of the free surface is constant, then the weight of the liquid does not affect the free surface effect.

- Within the ship position of the tank does not affect the free surface effect.

- When the tank is either empty or full, then the free surface effect is zero.

- Reducing the number of slack tanks decreases the free surface effect of the ship since the free surface effect of each tank adds to the total free surface effects of the ship.

- By fitting longitudinals in the tank, the free surface effect can be reduced to 1/(n+1)^2 of the FSC, n= no. of divisions.

- If a ship is listing (leaning to one side), filling the smallest tank on that side first helps correct the tilt. Initially, the Free Surface Effect (FSC) may worsen before the weight in the tank stabilizes the ship. So, acting quickly to fill the tank is crucial for safety.

Conclusion

Improper distribution of liquid within the tanks can destabilize the vessel due to sloshing, thereby highlighting the critical influence of the free surface effect (FSE) on stability. Minimizing slack tanks and dividing the tanks longitudinally can reduce the free surface effect and enhance the stability of the vessel.

If you want to learn more about the Inert Gas System, Click Here!

Frequently Asked Questions about Free Surface Effect

1. What is the free surface effect?

The tendency of liquids to move in response to changes in the altitude of the ship, rolling, pitching, etc other movement of the vessel at sea.

2. What is a slack tank?

A slack tank is a tank that is neither empty nor full is called slack tank.

3. How do you reduce the free surface effect?

Dividing the tanks longitudinally or pressing the tank up to full reduces the free surface effect.

4. What is the formula for the free surface correction of a tank?

This formula can be used to calculate the free surface correction.

FSC = (i * di) / (V * do)

5. What is the effect of the slack tank?

A partially full or slack tank imbalances the ship and causes it to lose its stability and rollover.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.