Fuel Oil System and Treatment Process for Marine Diesel Engines

Overview

- The fuel oil system has a major impact on the efficiency and dependability of marine diesel engines, which are the core of a ship’s propulsion system.

- The fuel oil system in marine diesel engines is a vital component that ensures the engine’s efficiency and reliability.

- The fuel oil system is designed to handle, treat, and distribute the proper quality and amount of fuel oil to the engine in various situations.

2:- Types of Fuel Used in Ships

Ships use various types of fuel, each chosen based on the type of vessel, the engine requirements, and environmental regulations. The main types of fuel used in ships include:

- Heavy Fuel Oil (HFO)

- Marine Diesel Oil (MDO)

- Marine Gas Oil (MGO)

- Liquefied Natural Gas (LNG)

- Liquefied Petroleum Gas (LPG)

- Methanol

- Biofuels

- Hydrogen

- Ammonia

| Fuel Type | Description | Advantages | Ignition Temperature (°C) | Other Key Factors |

| Heavy Fuel Oil (HFO) | Residual fuel oil left from refining crude oil | Cost-effective, widely available | 250 – 300 | High viscosity, requires heating |

| Marine Diesel Oil (MDO) | The blend of heavy fuel oil and marine gas oil | Easier to handle, cleaner burning than HFO | 250 – 350 | Lower sulfur content than HFO, moderate viscosity |

| Marine Gas Oil (MGO) | Distillate fuel oil similar to road diesel | Low sulfur content, cleaner burning | 250 – 300 | Low viscosity, does not require pre-heating |

| Liquefied Natural Gas (LNG) | Natural gas cooled to a liquid state | Lower emissions of SOx, NOx, and CO2 | -188 | Requires cryogenic tanks, low volumetric energy density |

| Liquefied Petroleum Gas (LPG) | Mix of propane and butane, stored as a liquid | Clean burning, reduces SOx and NOx emissions | 365 – 470 (Propane) | Requires pressurized storage, moderate energy density |

Click here to learn the additives used in the Fuel Oil of Ships.

3:- Heavy Fuel Oil (HFO) from Crude Oil

3.1:- What is Crude Oil?

- Crude oil is a naturally occurring, unrefined petroleum product composed of hydrocarbon deposits and other organic materials.

- It is a fossil fuel formed from the remains of ancient marine organisms such as plants, algae, and bacteria, which were buried under layers of sediment and rock for millions of years.

- These layers’ high pressure and heat transformed the organic material into crude oil. It is extracted from the earth and undergoes a series of complex processes to produce different fuels and by-products.

3.2:- Treatment of Crude Oil

1. Heating Crude Oil in a Furnace

- Initial Heating

- The initial heating of crude oil is essential to convert it into the vapor phase, which is necessary for the subsequent distillation process.

- Crude oil is fed into a furnace where it is heated to around 400°C.

- At this high temperature, the crude oil vaporizes, allowing for the different components with varying boiling points to be separated during distillation.

2. Distillation Process

- Primary Distillation (Atmospheric Distillation):

- The vaporized crude oil enters a distillation column, also known as a fractionating column.

- As the vaporized crude oil rises through the column, the temperature decreases. Components with different boiling points condense at various levels within the column.

- Top of the Column: Lighter fractions with lower boiling points, such as gases (methane, ethane), gasoline, and naphtha, are collected here.

- Middle of the Column: Medium fractions like kerosene, diesel, and jet fuel condense and are drawn off at this level.

- Bottom of the Column: Heavier fractions with higher boiling points, such as heavy fuel oil and lubricating oil, are collected at the bottom.

- The heaviest components, often referred to as “residuum” or “bottoms,” remain as a thick, viscous liquid. This residue contains heavy hydrocarbons that have not vaporized.

3. Further Processing (Vaccum Distillation)

- The atmospheric distillation residue is subjected to further heating and processing in a vacuum distillation unit to extract more valuable products.

- By reducing the pressure (vacuum), the boiling points of the remaining heavy hydrocarbons are lowered, allowing them to vaporize at lower temperatures and be separated.

- This step produces additional valuable fractions like heavy gas oils, lubricating oils, and waxes. The remaining residue after vacuum distillation can be used for bitumen production or as a feedstock for further processing.

4. Cracking Process

- The remaining residue is then processed through cracking, which breaks down large hydrocarbon molecules into smaller ones.

- There are two types of cracking:

- Fluid Catalytic Cracking (FCC): Uses a catalyst to lower the temperature and pressure needed for cracking, producing lighter fuels.

- Thermal Cracking: Uses high temperatures and pressures without a catalyst, resulting in a different range of products.

After these processes, what is left is the bunker fuel oil, or HFO, ready to be used in marine engines.

5:- HFO Handling and Preparation Onboard

Onboard ships, Heavy Fuel Oil (HFO) is crucial for powering engines and maintaining operations. The handling and preparation of HFO start with bunkering, where the fuel is loaded onto the ship and stored in dedicated storage tanks.

These tanks are designed to safely hold the heavy and viscous fuel until it is needed for use. When the ship requires fuel for its engines, the HFO is transferred from the storage tanks to smaller service tanks located closer to the engines.

5.1:- What is Bunkering?

Bunkering refers to the process of supplying fuel, typically marine fuel, to a ship. It involves the transfer of fuel from a bunkering barge or tanker to the ship’s storage tanks. A bunkering tank is a storage tank on a ship used to hold fuel that has been bunkered. These tanks are specially designed to safely store large quantities of fuel and are an essential part of a ship’s infrastructure for fuel management.

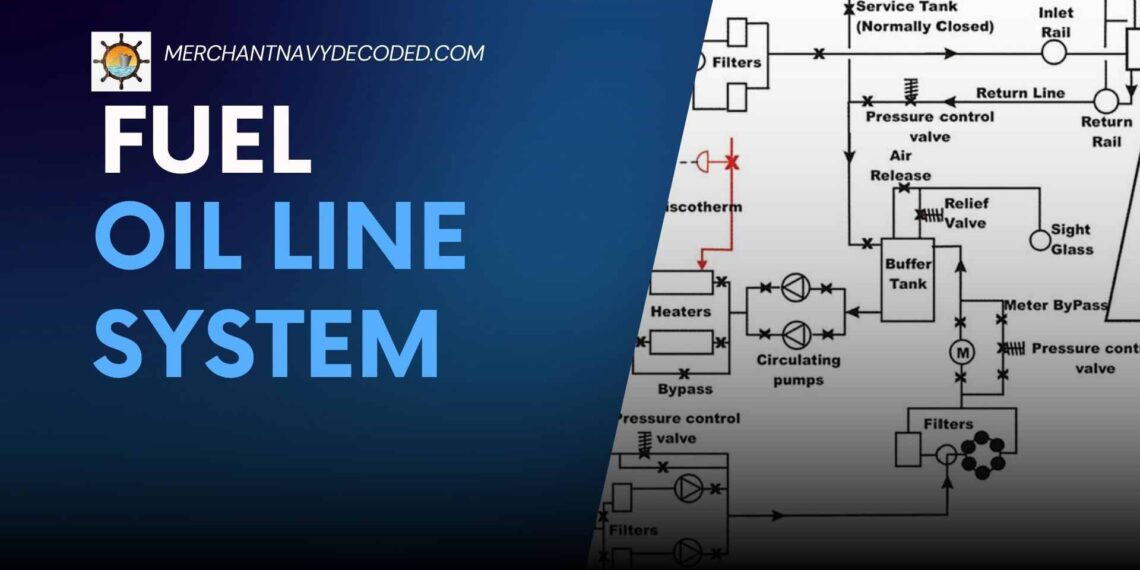

6:- Fuel Oil Line Components and Functions

6.1:- Filters and Pumps

Heavy Fuel Oil (HFO) undergoes initial treatment as it passes through filters and pumps. Here, it is filtered to remove contaminants and pressurized to around 4 to 5 bar for efficient flow through the system.

- Auto-backwash and Manual Filters:

- Auto-backwash Filters: These filters automatically clean themselves by reversing the flow to flush out contaminants, ensuring continuous filtration efficiency.

- Manual Filters: These filters require periodic manual cleaning and serve as a secondary filtration step to ensure fuel quality.

6.2:- Fuel Oil Meter

A fuel oil meter is used to measure the consumption of fuel, enabling efficient monitoring and management of fuel usage onboard.

6.3:- Pressure Control Valve

- Pressure Control Valve: This valve maintains a consistent pressure in the fuel line, ensuring optimal performance of the system.

6.4:- Buffer Tank

The fuel then enters a buffer tank, where the level is carefully maintained. Air vents and pressure relief valves are crucial here to prevent over-pressurization and ensure safety.

6.5:- Booster Pump and Further Heating

- Booster Pump: Increases the fuel pressure to 10 bar for efficient delivery to the engine.

- Further Heating: The fuel is heated to around 85°C to reduce its viscosity, ensuring smooth flow through the system and optimal combustion.

6.6:- Viscosity Control System

- Heater and Viscosity Controller (Viscotherm): This system maintains the appropriate fuel viscosity for optimal combustion.

- Working Principle: It measures the fuel viscosity and adjusts the temperature to maintain it within desired limits.

- Importance: Proper viscosity is crucial for efficient fuel injection and combustion, preventing engine wear and maximizing performance.

6.7:- Final Delivery to the Engine

Finally, the fuel is delivered to the pump, which injects it into the main engine, ensuring smooth and efficient operation.

Click here to learn more about the fuel Storage and Distribution system of the ship.

7:- What is Viscotherm?

A viscotherm is a viscosity monitoring device or viscosity controller used in fuel oil systems. It measures the viscosity of fuel oil and helps regulate the fuel heating process to maintain optimal viscosity for efficient combustion in engines.

7.1:- Working Principle of a Viscotherm

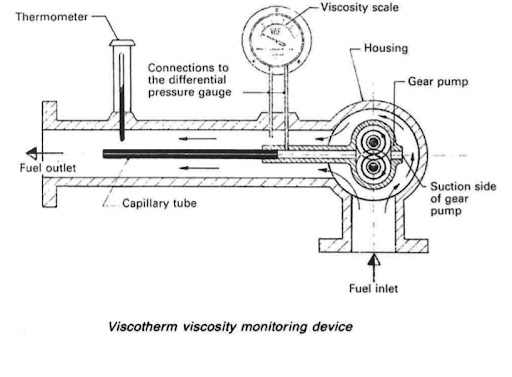

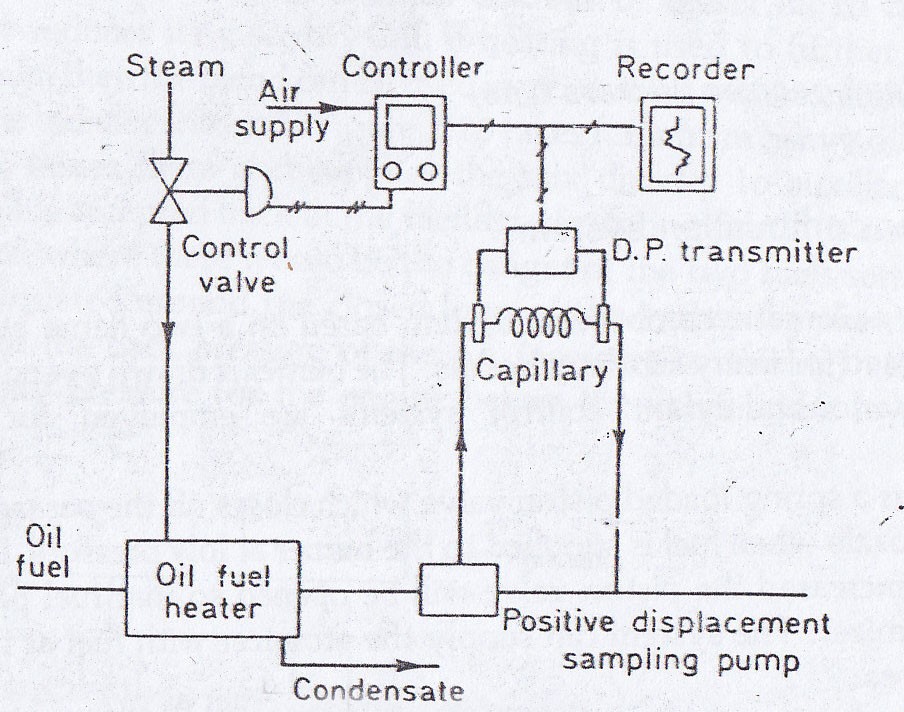

- The Viscotherm viscosity controller works by pumping a continuous sample of fuel oil through a fine capillary tube at a constant rate. As the fuel flows through the tube in a smooth and orderly manner (laminar flow), the pressure drop across the tube is directly related to the viscosity of the fuel.

- This pressure drop is measured by a differential pressure gauge calibrated in terms of viscosity. The gauge provides an analog signal of the viscosity to a pneumatic controller, which then regulates the supply of fuel heating steam through a control valve.

- By adjusting the supply of heating steam based on the viscosity measurement, the Viscotherm ensures that the fuel oil maintains the correct viscosity for efficient combustion in engines.

7.2:- What is the Viscosity of Marine Diesel Oil?

- Diesel oil, commonly known as Marine Diesel Oil (MDO) or Marine Diesel Fuel (MDF), has a density of around 0.9 g/cm3. It has a flash point above 60°C and a calorific value of about 44000 kJ/kg. The kinematic viscosity of diesel oil is approximately 8 to 11 cSt at 40°C, and it has a sulfur content of around 2%. Diesel oil is typically brownish.

7.3:- Purpose of By-Pass Line in Fuel Oil Line

- The bypass line in a fuel oil system serves as a secondary pathway for the fuel to flow in case of a blockage or pressure build-up in the main fuel line. It is typically located parallel to the main fuel line and includes a valve that can be opened or closed to control the flow through the bypass.

- The bypass line ensures uninterrupted fuel supply to the engine by allowing fuel to bypass the blockage or pressure build-up and continue flowing to the engine.

Conclusion

In conclusion, crude oil treatment is a complicated process that includes heating, distillation, further processing, and the handling of heavy fuel oil (HFO) for engine usage. Each stage is critical in refining crude oil into marketable products like petrol, diesel, and lubricating oil. Understanding this process is critical for the effective manufacture and application of fuel oil in a variety of industries, including marine and energy.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.

Sir, i want to know that when the fuel finish from earth how will ships run, i know there is more wasy to run ship like nuclear power, steam , gas, electric, but the diesel is top one because of its efficiency, torque, power, but when fuel finish.

Q1 : what is the future of merchant navy.

Q2 : how in future merchant navy vessels run.

Q3 : my father says that change your mind from it.

Q4: i want to become marine engineer after my b.tech right know in 3 year 6 sem.

Q4: should i change my mind or not.

Q5 : my says that there is so much politics in merchant navy as well as ship.

Q6 : what is future of GME aspirant in future is there any problem.

Q7 : job security in future.

I take mechnical engineering because of merchant navy my father used to say that why you not take computer science and i always think that i will prove that my mechnical engineering is a good choice.

Hi Hitesh, we have forwarded this to Sir, very soon you will have a dedicated video answering all your questions.

Very good information sirji