Types of filter in ship

A filter is a porous device for removing impurities or solid particles from a liquid or gas passed through it. Filters are being used in our day to day lives as well.

Example:

- Sieving flour

2. Making tea

3. Air filter in Honda Activa

4. Oil filter in a bike

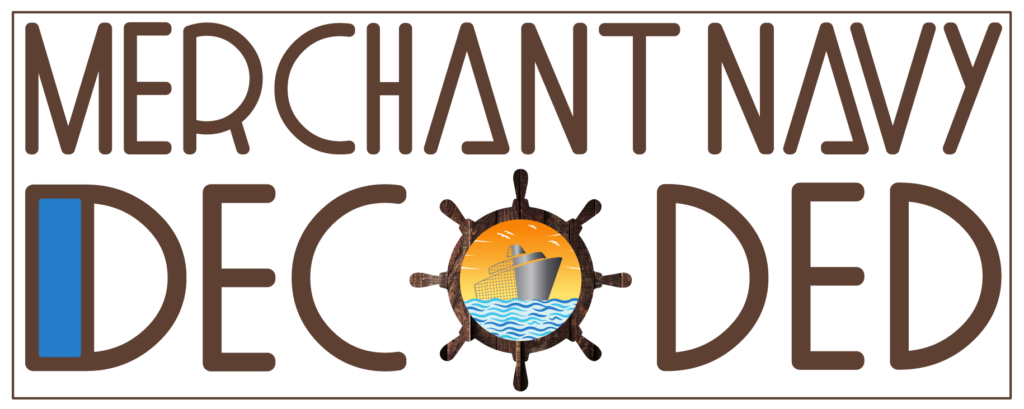

Filters are fitted onboard ship in different systems like:

- Fuel oil system

- Lube oil system

- Seawater system

- Fresh water system

- Steam system

- Compressed air line

Filters can be of different sizes, ranging from being huge to being as small as the size of a finger.

Filters are not just differentiated in terms of their size but also in terms of their mesh size (hole diameter of filters through which fluid passes). The mesh size of a filter can be as big as 5 mm to as small as 10×10° meters.

Types of filter used onboard:

- Oil filters

- Water filter

- Air filters

- Special Filters

Oil filters:

Oil filters are used onboard ships to remove impurities and contaminants from the oil that is circulated throughout the ship’s machinery and engines. Oil filters can be used for different purposes like cleaning lube oil, fuel oil, and hydraulic oil.

Different types of oil filters are:

i. Fine mesh screen filter: These filters are particularly used in fuel oil (FO) and lube oil (LO) systems. These filters are commonly integrated into cylinder oil, main engine, and auxiliary engine fuel oil and lube oil, as well as boiler fuel oil systems. They are the predominant choice for filtering purposes in these systems.

ii. Magnetic filter: Magnetic filters, known for their magnetic properties, effectively capture ferrous materials by drawing them in. These filters feature a basket-like screen that enhances their filtering capabilities. They are predominantly employed in lube oil systems, as lube oil tends to contain a higher concentration of ferrous metal particles. This ensures added protection for engines and gearboxes, where the presence of ferrous particles is more probable.

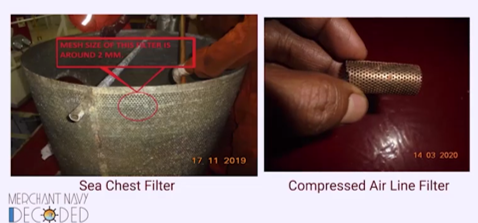

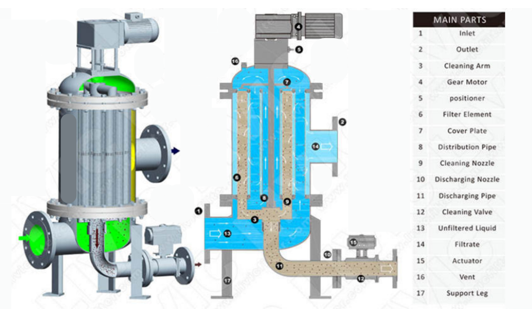

iii. Auto Back wash filter: An auto backwashing filter is a self-cleaning filtration system that automatically reverses the flow of water or fluid through the filter media to remove accumulated debris and maintain its efficiency.

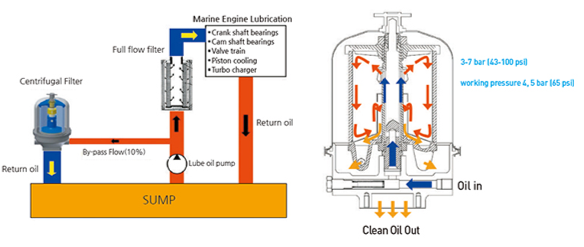

iv. Centrifugal filter: Auto backwashing filters operate based on the principles of centrifugal force and substance density. By harnessing centrifugal force, these filters effectively separate impurities with higher density from the lower density fluid. This type of filter is widely utilized in the lube oil system of auxiliary engines for efficient filtration.

Water filter:

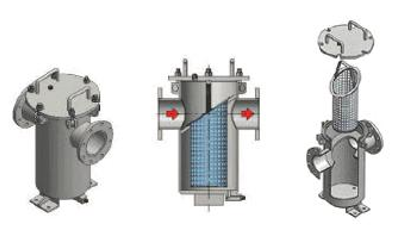

Filters (strainers) are installed in both the sea water and fresh water systems on board ships to capture solid impurities. In general, the sea water system tends to have a higher number of filters compared to the fresh water system.

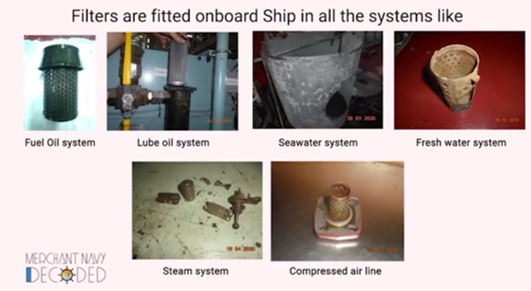

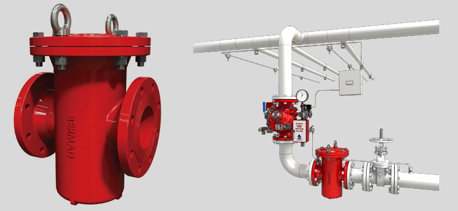

i. Sea chest filter: A sea chest filter is a type of filter used in marine vessels to prevent debris and marine organisms from entering the cooling system. It is typically installed at the intake point where sea water is drawn into the ship for various purposes such as cooling engines or equipment. The sea chest filter is designed to capture larger particles and organisms, protecting the ship’s systems from potential damage or clogging. Regular maintenance and cleaning of the sea chest filter are necessary to ensure its effective operation.

ii. Fire line suction filter: The sea chest filter utilized in the main fire line employs a medium screen mesh size to effectively filter the sea water. This ensures that larger particles and impurities are captured, providing reliable protection for the fire suppression system onboard the vessel.

iii. Bilge line filter: The cylindrical strainer used in the suction side of the bilge line is typically equipped with large screen mesh size or holes. This design enables effective filtration of mud, rags, and dirt, preventing these contaminants from entering the system. The strainer serves as a safeguard, ensuring the smooth operation and functionality of the bilge system by capturing and removing unwanted debris.

iv. Fresh water line: Filters in the fresh water system are installed on the suction side, employing a small-sized screen mesh. This configuration allows for efficient filtration, capturing and preventing smaller impurities from entering the system. By placing the filters on the suction side, the fresh water system is effectively protected from contaminants, ensuring the supply of clean and purified water for various onboard applications.

Air filter:

Moisture filters are commonly employed on ships to improve the performance of control systems, turbochargers, Inert Gas (IG) systems, and compressors. These filters ensure that high-quality air is supplied, optimizing machinery efficiency.

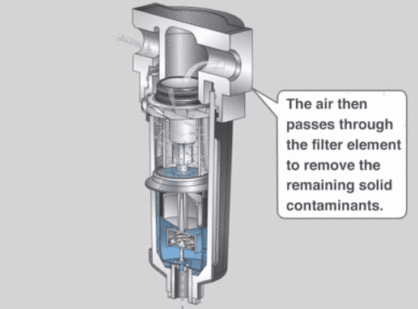

i. Control air filter: Moisture filters play a crucial role in the smooth operation of pneumatic systems. They effectively eliminate moisture from compressed air, which is typically discharged by the control air compressor. By doing so, these filters ensure the efficient functionality of the pneumatic system.

ii. Turbocharger filter: Copper mesh filters are utilized on the intake side of compressors (blowers) to safeguard against the entry of carbon, dirt, and particles. These filters effectively prevent such contaminants from entering the blower, maintaining its optimal performance and longevity.

iii. Compressor suction filter: The installation of these filters ensures that only clean, pure air is drawn into the compressor, effectively safeguarding the internal components against potential damage caused by foreign materials.

Special filter:

Special filters refer to filters that are specifically designed or utilized for particular purposes.

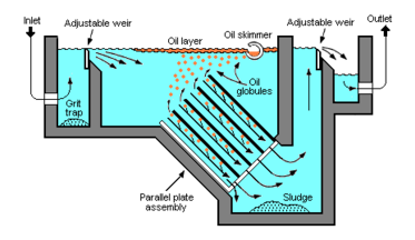

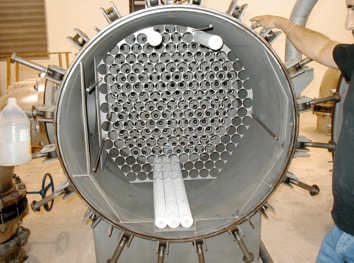

i. OWS filter: The oily water separator incorporates filters in both stages of separation. In the first stage, a simple felt filter is employed, while in the second stage, a more expensive coalescer filter is utilized.

ii. Cartridge filter: The filter is designed in a cartridge-like structure, allowing for easy replacement or cleaning simply by removing the cartridge. This type of filter is commonly employed in portable machinery such as generators and compressors. Typically, it follows a duplex configuration.

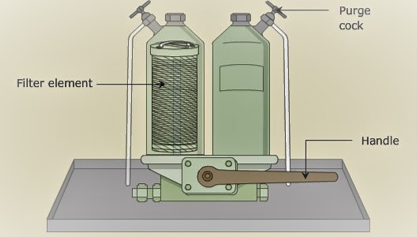

iii. Duplex filter: The utilization of a duplex filter implies that filters are arranged in pairs, enabling easy maintenance by facilitating the removal of one filter while the other remains operational. This system is commonly adopted for all filters on ships, providing a convenient maintenance approach.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.