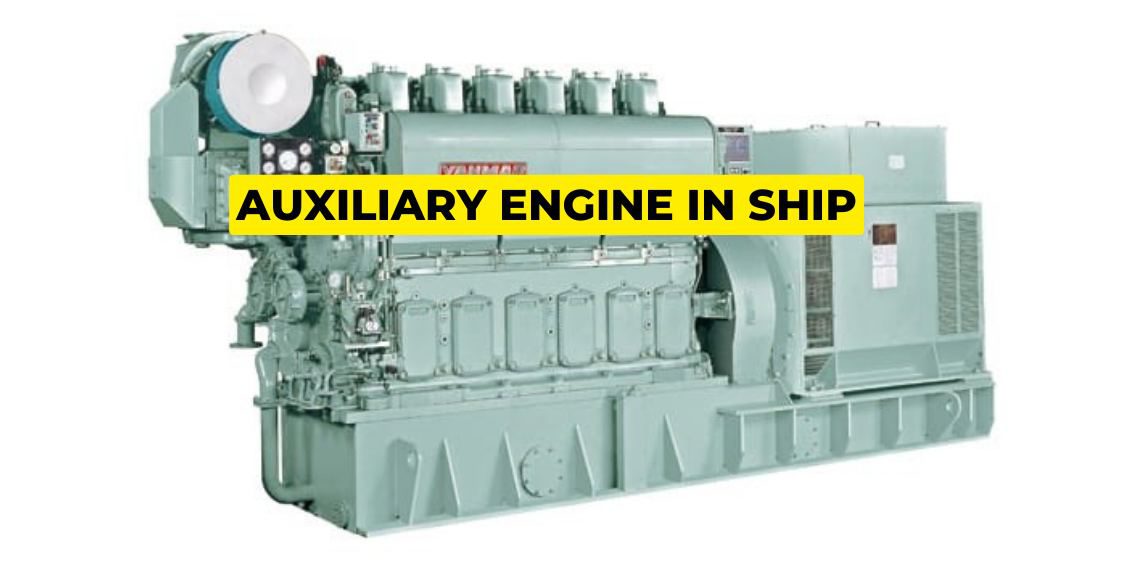

What is Marine Auxiliary Engine

1:- Auxiliary Engine Introduction

An auxiliary engine onboard a ship is smaller than the main engine, which is used to provide power for various essential functions other than propulsion.

The main engine drives the ship’s propeller and auxiliary engines generate electricity to power essential systems like lighting, air conditioning (HVAC), navigation equipment (bridge equipment), communication devices, pumps, and other machinery required for the safe and efficient operation of the ship.

2:- How Power is Generated and Distributed onboard the Ship?

Generation of Electricity

- The ship’s auxiliary engines are usually diesel engines (Prime mover), which drive an alternator.

- The alternator converts mechanical energy from the engine into electrical energy. It operates on the principle of electromagnetic induction, where the rotation of the engine shaft turns the rotor inside the alternator, generating an alternating current (AC).

- The generated electricity typically has a voltage of 440V and a frequency of 60 Hz or 50 Hz, depending on the ship’s design and region of operation.

Distribution of Electricity:

- The electricity generated is fed into the main switchboard (MSB), The Main switchboard is a metal box that serves as the central distribution center for all the essential loads. The MSB regulates and distributes power to various machinery systems on the ship.

- The main switchboard distributes power to different electrical circuits based on the ship’s load requirements. These circuits supply power to:

- Lighting Systems

- Heating, Ventilation, and Air Conditioning (HVAC)

- Navigation and Communication Equipment

- Pumps and Motors

- Galley Equipment

- Cargo Handling Gear

- Safety Systems (e.g., emergency lighting, alarms)

If you find auxiliary engines a difficult topic to tackle, then fret not, we have just the right package for you that will help you to clear all your concepts of auxiliary engines.

3:- Synchronizing Generator on Ship

Synchronizing generators on ships is important for parallel operation, ensuring stable and efficient power distribution. Before paralleling, it is essential to match the frequency and voltage of the incoming generator with the running generator. This process is typically achieved using a synchroscope or the three-bulb method.

4:- What is the Synchroscope and Three-Bulb Method?

The synchroscope visually indicates when the generators’ frequencies are aligned, while the three-bulb method provides a simpler, emergency solution by observing the brightness of three light bulbs connected to the generator terminals.

Proper synchronization prevents electrical imbalances, reduces equipment wear, and ensures a reliable power supply, making it a critical procedure for shipboard power management.

4.1:- Key Requirements for the Successful Synchronization of Generators

To successfully synchronize generators, the following conditions must be met:

- Phase Sequence: The phase sequence of the incoming generator must match the bus bar’s phase sequence.

- RMS Voltage Magnitude: The RMS voltage of the incoming generator must be equal to the bus bar’s RMS voltage.

- Frequency: The generator’s frequency must align with the bus bar’s frequency.

- Phase Angle: There should be no phase angle difference between the generator’s voltage and the bus bar’s voltage.

Meeting these requirements ensures stable and efficient generator operation.

5:- Blackout Situation Onboard Ship

A blackout situation on a ship is a complete loss of electrical power across all systems, including propulsion, navigation, and safety equipment.

Blackout can occur due to a failure in the power generation system, such as generator malfunction or fuel shortages, or due to a fault in the power distribution system.

During a blackout, the ship becomes unable to operate its essential systems, posing serious risks to safety and navigation. During Blackout immediate measures, including emergency power systems and manual control, are critical to restore power and ensure the ship’s safety and operational integrity.

5.1:- What should you do in case of a Blackout Onboard?

In case of a blackout, follow these steps and precautions:

- Inform the Officer on the Bridge: Briefly update the officer on the bridge about the condition and call for additional manpower. Inform the Chief Engineer.

- Fuel Management: If the main propulsion plant is running, set the fuel lever to the zero position. Close the feed to the running purifier to prevent overflow and fuel wastage.

- Auxiliary Boiler: If the auxiliary boiler was running, shut the main steam stop valve to maintain steam pressure.

- Identify and Rectify: Determine the cause of the blackout and address the issue.

- Pre-Lubrication: Before starting the generator set, ensure pre-lubrication by using the priming pump. If the emergency generator supplies this, use it; otherwise, use the manual priming handle.

- Start the Generator: Start the generator, take it on load, and then immediately start the main engine lubricating oil pump and the main engine jacket water pump.

- Reset Breakers: Reset the breakers and start all essential machinery and systems, following the preferential tripping sequence. Non-essential machinery should be restarted as needed.

6:- Starting and Stopping of Generator

6.1:- Starting the Generator

- Automatic Start:

- Precondition is an important step before starting the generator so check for the sufficient starting air must be available.

- The generator can start automatically based on load requirements without operator (engineer)intervention.

- During maneuvering or in restricted areas, the operator may need to manually start the generator using the Power Management System (PMS). This is done by accessing the PMS, navigating to the generator digital system, and clicking the “Start” button.

- The Power Management System handles the sequence of starting, matching the voltage and frequency, and bringing the generator online automatically.

- In cases of blackout or dead ship conditions, a manual start may be necessary.

- Manual Start:

- Primary step is to ensure all necessary valves are open and no interlock is active on the generator.

- Open the indicator cocks and give a small air kick using the starting lever to check for water leakage. Return the lever to zero position.

- Local Start by setting the control to local mode and start the generator locally.

- If water leakage is detected, report it to a senior officer and take appropriate action.

Note that this procedure is not generally followed on Unattended Machinery Space (UMS) ships but is common in manned engine rooms.

- After checking for leaks and closing the indicator cocks, start the generator again. Allow it to run with no load for about 5 minutes.

- Switch the generator to remote mode. If automation is functioning, the generator will come online automatically.

- If manual intervention is required, check the voltage and frequency using the generator panel in the Engine Control Room. Use the synchroscope to ensure correct synchronization.

6.2:- Stopping the Generator

- Automatic Stop:

- Access the PMS, and press the “Stop” button to begin shutting down the generator.

- This should only be done when multiple generators are running.

- The PMS gradually reduces the load before stopping the generator.

- If only one generator is running, it will not stop automatically due to safety systems in place to prevent a blackout.

2. Manual Stop:

- Gradually reduce the generator load using the governor control on the panel.

- Once the load drops below 100 kW, press the breaker to take the generator off-load.

- Allow the generator to run for 5 minutes at idle before pressing the stop button on the panel.

- Finally, press the stop button to fully shut down the generator.

7:- Use of Marine Auxiliary Engine

The purpose of a marine auxiliary engine is to provide electrical power and hydraulic power for the ship’s various systems and equipment. These systems can include:

7.1:- Electrical Power Generation

Auxiliary engines are used to generate electricity for lighting, communication, navigation, and other essential systems.

7.2:- Pumping Systems

Auxiliary engines are also used to power the various pumps on the ship, including bilge pumps, fire pumps, and ballast pumps.

7.3:- HVAC Systems

Auxiliary engines provide power to the heating, ventilation, and air conditioning (HVAC) systems on the ship.

7.4:- Other Equipment:

Auxiliary engines can also provide power for other equipment on the ship, such as cranes, winches, and other machinery.

8:- Why do we use four stroke engines on ships as an auxiliary engine?

Four-stroke engines are commonly used as auxiliary engines on ships instead of two-stroke engines for several reasons:

1. Flexibility:

Four-stroke engines are more flexible in terms of their power output and can be adapted to different power requirements. This makes them suitable for use as auxiliary engines on ships, where power demands can vary widely.

2. Lower Operating Costs:

Four-stroke engines are generally more fuel efficient than two-stroke engines at low and medium loads, which is where auxiliary engines typically operate. This means that they can help to reduce the operating costs of a ship.

Transformers may be used to step down or step up the voltage for certain equipment that requires lower voltage or higher voltage, such as lighting (220V or 110V systems).

AC 3 Phase power is preferred onboard over DC because it gives more power for the same size of wire, it delivers more power efficiently, ensures a constant and smooth power flow, improves motor performance, and balances the load better.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.