Bunkering & Bunkering Operation

1. Introduction

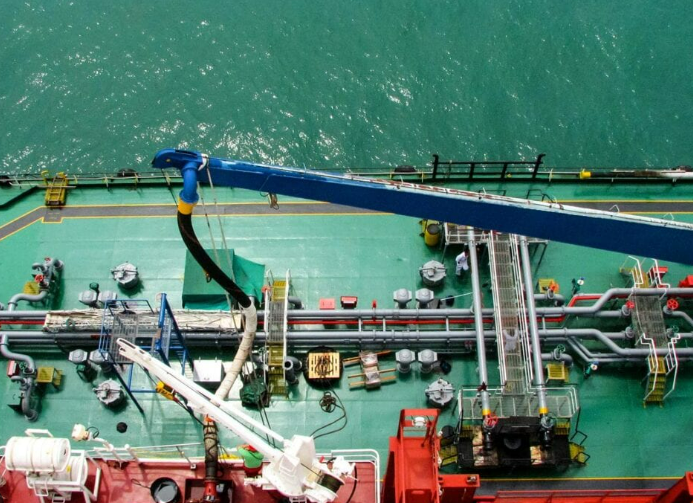

The term bunkering is typically associated with the shipping industry. Bunkering refers to the process of refueling the vessel for its regular operations. It involves the transfer of fuel, such as marine fuel oil from shore-based barges or from the bunker vessels to the fuel tank on board the vessel.

Bunkering is a regulatory process and therefore there are various standards, guidelines, and regulations regarding the bunkering process. These standards are set by the International Maritime Organisation (IMO), which ensures the safety of the environment and the quality of fuel supplied to the vessel.

To get more such information regarding the deck side of a ship like ship stability, ship construction, colregs, etc visit our DECK DREAMER package.

2. Procedure of Bunkering

The engineer in charge of the bunkering procedure should be fully conversant with the oil transfer and the pumping arrangement.

Procedures for bunkering can be further divided into three parts:-

2.1 Pre-Bunkering Checks

- Before starting the bunkering process you should calculate the remaining oil on board (ROB) and must get the sounding of the tanks by applying proper trim and heel correction.

- The high-level alarm on the bunker tanks should be tested and confirmed okay before bunkering. Alarms should never be bypassed or turned off.

- No bunker tanks should be planned to be filled up with more than 90% of the total capacity of the vessel, leaving 10 percent for the expansion of the oil to the temperature of the environment.

- Before starting the bunkering your sounding pipe, air pipe, dip tray, etc shall be cleaned and plugged.

- During bunkering at night proper lighting should be there to illuminate the manifold area, pipelines, trays, vents, etc.

- All pressure gauges have to be operated, in addition to scuppers and openings on the main deck should be checked.

- Before bunkering starts have a look that there should not be any oil sheens or patches on the ship sides.

2.2 During bunkering

- During bunkering check and confirm that tanks where bunkers are to be taken have their vents open to prevent overpressurization of tanks.

- Once all the valves and hoses are checked the supplier can be asked to start at a slow rate.

- The rate of bunkering can be increased after ensuring that there is no leakage or other such problems.

- During the bunkering process, you have to take a sample of the fuel from the dip tray at the manifold for test.

- As the topping-up stage approaches the bunkering flow is again regulated so that the tank can be secured one at a time.

2.3 After bunkering

- Confirm and ensure that the barges ashore have stopped pumping.

- Make sure that sufficient space is left in the tank so that oil inside the pipe can be filled while draining.

- The manifold valve shall be kept fully open, it is good practice to keep the sounding pipe closed.

- Clean and empty dip trays should be kept under the manifolds while disconnecting the bunker hose.

- Make sure blanks are fitted with proper gaskets.

- At last proper entries shall be made in the Oil Record Book.

3. Frequently Asked Question

Q1:- What are the types of bunkering?

Ans:- There are mainly two types of bunkering processes i.e.

- Pipe to ship

- Ship to ship

Q2:- What is the purpose of bunkering lines?

Ans:- The purpose of bunkering lines is to supply fuel and gasoil to power a ship’s propulsion system from one ship to another.

Q3:- What precautions are needed during a bunkering process?

Ans:- 1. Make sure valves to unused tanks are closed.

2. Ensure two-way communication with the delivering vessel or facility.

3. Maintain two-way communication with the bunker team.

4. Notify the delivering vessel or facility before changing tanks and topping off.

Q4:- How many hours does bunkering take?

Ans:- The bunkering process takes around 14 to 16 hours.

Q5:- What is bunkering?

Ans:- Bunkering is a process where barges carrying fuel will be moved alongside a vessel with the assistance of tugboats to transfer oil from one ship to another.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.